When you're installing a metal roof, adding insulation isn't just an optional extra—it's a critical part of the job. By installing a thermal barrier, usually a combination of reflective foil and insulation batts, you're doing more than just managing temperature. You're creating a more comfortable, energy-efficient, and quieter space. A reliable roofing company will tell you this is one of the most important steps to get right from the very beginning.

Why Insulating Your Metal Roof Is Essential

A metal roof is a brilliant choice for longevity, but its knack for conducting heat can be a real challenge. Without a solid layer of insulation underneath, your roof can act like a giant radiator. In summer, it soaks up the sun's heat and beams it straight into your home, and in winter, it lets all that cosy warmth escape. This hits you in two places: your comfort and your energy bills.

The main problem is heat transfer. Metal is a far better conductor of heat than materials like terracotta or concrete tiles. On a hot summer day, that heat travels quickly from the metal sheets down into your living spaces, making your air conditioning work much harder just to keep things bearable. The opposite is true in winter, as your heating fights a losing battle against the cold metal overhead.

The Australian Context for Metal Roof Insulation

Metal roofing is incredibly popular here in Australia. In fact, in 2024, it’s expected to make up around 52.8% of all new residential roofs. From the tropical humidity of North Queensland to the cooler climate of Victoria, its widespread use makes proper insulation a non-negotiable part of any build.

Since metal is such an efficient heat conductor, an uninsulated roof offers next to no thermal resistance (or R-value). This is what leads to those scorching hot interiors during our summers and chilly rooms in the cooler months. Getting the insulation right isn't just about feeling comfortable; it's one of the best ways to slash your energy consumption.

Australia's National Construction Code (NCC) sets clear minimum standards for energy efficiency. A reliable roofing company will meet these requirements by using smart insulation solutions. For instance, reflective barriers can block up to 97% of radiant heat, which makes a massive difference to your cooling costs.

Beyond Temperature Control

While keeping temperatures stable is the main goal, insulating a metal roof brings a few other key advantages to the table. One of the biggest is acoustic dampening. It significantly muffles the drumming sound of heavy rain or hail, which can otherwise be a major downside of metal roofing.

Insulation is also your number one defence against condensation. When warm, moist air from inside your home hits the cold underside of a metal roof sheet, condensation can form. Over time, this can lead to serious problems like mould, mildew, and even damage to the roof structure itself. A quality insulation system, often including a vapour barrier, stops this from happening.

If you’re planning a new build or getting ready for a reroof, it’s vital to factor this in from the start. We dive deeper into how to integrate insulation during the construction phase in our complete metal roof installation guide. At the end of the day, investing in proper insulation for your metal roof is a smart move that pays off in comfort, efficiency, and the long-term health of your property.

How to Choose the Right Insulation for Your Climate

When it comes to insulating a metal roof, picking the right material isn't a one-size-fits-all job. It’s about getting the right solution for your home and, crucially, for the Aussie climate you live in. The decision you make here will have a massive impact on your home's comfort through scorching summers and chilly winters, not to mention your power bills.

A reliable roofing company can walk you through the options, but it pays to understand what you're looking at first.

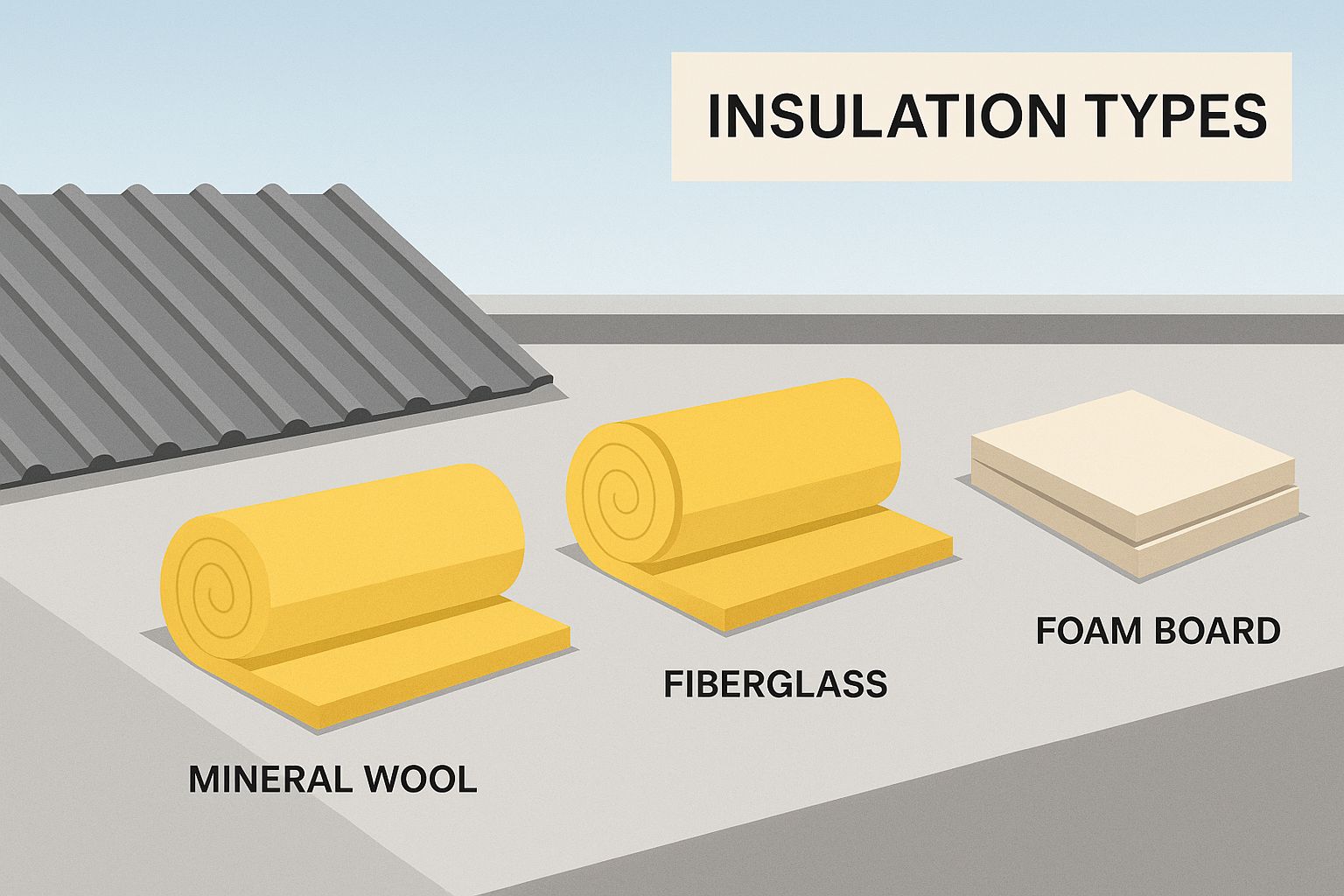

This image gives a handy visual guide to the most common types of insulation you'll see used in metal roofing projects.

As you can see, from simple rolls to rigid boards, each material has its own strengths. The trick is matching the right product to your roof and your specific needs.

Matching Insulation Materials to Your Local Environment

Different parts of Australia throw different challenges at a roof. What works perfectly in a dry, inland town might not be the best bet for a humid coastal city.

For instance, if you're in a humid, coastal area like Sydney or Brisbane, keeping moisture out is just as vital as blocking heat. Our reliable roofing team has seen countless issues with condensation when warm, moist air hits a cool metal roof. This is where closed-cell spray foam insulation really shines. It creates a complete air and vapour barrier, stopping condensation in its tracks.

On the other hand, if your home is in a drier, inland region, you can take a different, often more cost-effective, route. Reflective foil-backed fibreglass batts are a brilliant choice here. They give you solid thermal resistance and, more importantly, reflect the intense radiant heat that beats down on roofs in sunny climates. It's a great performer for a more accessible price.

Getting a Grip on R-Values

You'll hear the term "R-value" thrown around a lot. It's simply a measure of how well an insulation material resists heat flow—the higher the R-value, the better the insulation. But these aren't just numbers on a spec sheet; they directly translate to how comfortable your home will be.

Think of it this way: homeowners in warmer parts of Australia are often looking for a total R-value of around R4.1, while those in more temperate zones might aim for R3.4. Hitting the right target for your climate zone is key to meeting energy codes and getting the best bang for your buck on energy savings.

Picking the right materials to insulate a metal roof in Australia means balancing thermal performance with moisture control. While spray foam often costs 20-30% more than fibreglass, its superior air-sealing and higher R-value (around R-2.1 to R-2.7 per 25mm) make it incredibly effective. It’s particularly good at stopping moisture build-up by sealing all those tiny gaps where condensation loves to form.

Fibreglass batts are still a popular and budget-friendly option, but they have to be installed perfectly to work well. A good middle-ground is rigid foam board, which offers decent thermal performance and is quite durable. For more tips on making your roof as efficient as possible, you can find some great information from the best roofing experts online.

Choosing the best option comes down to a careful balance of cost, desired performance, and the realities of your local climate.

To help you compare the most common options at a glance, here’s a quick breakdown.

Insulation Material Comparison for Australian Metal Roofs

| Insulation Type | Typical R-Value (per 25mm) | Pros | Cons | Best For |

|---|---|---|---|---|

| Fibreglass Batts | R0.6 - R0.8 | Affordable, widely available, good sound absorption. | Can lose effectiveness if compressed or wet; requires a separate vapour barrier. | Budget-conscious projects in dry to moderate climates. |

| Spray Foam (Closed-Cell) | R2.1 - R2.7 | Excellent air and vapour barrier, high R-value, seals gaps. | More expensive, requires professional installation. | Humid coastal areas and homes where airtightness is a priority. |

| Rigid Foam Board | R1.0 - R1.8 | Durable, good moisture resistance, consistent R-value. | Joints must be taped to prevent air leaks; can be brittle. | Applications needing a durable, stable insulation layer. |

| Reflective Foil | Varies (blocks radiant heat) | Excellent at reflecting radiant heat, lightweight. | Provides little thermal resistance (R-value); must have an air gap to work. | Hot, sunny climates as a supplement to bulk insulation. |

This table should give you a clearer idea of where each material excels and help you start the conversation with your roofing professional.

Why You Should Always Talk to a Pro

Trying to sort through all these options can feel overwhelming. This is exactly why getting advice from a reliable roofing company is so important.

A seasoned professional will do more than just sell you a product. They’ll assess your roof’s design, your specific climate, and your budget to recommend the right materials. Most importantly, they'll make sure the entire system is installed correctly and complies with the National Construction Code (NCC) and any local council rules. This expert guidance from a reliable company turns a confusing decision into a confident investment, giving you peace of mind that your roof will perform for years to come.

A Practical Guide to Metal Roof Insulation

Once you've got your materials sorted, it’s time to get hands-on and actually install the insulation. This is where the real work begins, and your careful planning will start to pay off. You’ll see a direct improvement in your home's comfort and energy bills when this is done right.

Every type of insulation has its own quirks, but the basic rules are always the same: work safely, be precise, and don’t cut corners.

A sloppy job can completely undo the benefits of even the priciest materials. You could end up with thermal gaps, moisture problems, or just a disappointing result that doesn’t perform as promised. A bit of patience here goes a long way.

Essential Prep Work Before You Start

Before a single piece of insulation goes up, you need to get the space ready. Think of it as laying the groundwork—get this right, and the rest of the installation will go much smoother and you'll head off potential problems down the track.

First things first, get the roof cavity or attic space spotlessly clean. Any dust, old building scraps, or general rubbish will get in the way and can compromise how well the insulation fits and works. It’s worth the effort to vacuum the rafters and surfaces for a clean slate.

While you're up there, it's the perfect chance to play detective and check for any existing problems.

- Hunt for Leaks: Keep an eye out for water stains or any hint of moisture on the timber frame or the underside of the roof deck. If you find anything, you absolutely must get a reliable roofer to fix the leak before you even think about insulating.

- Check the Wiring: Take a good look at any electrical wiring. Is it in good nick? Is it properly secured? Some types of insulation can’t just be jammed up against wiring, so you need to know what you're dealing with.

- Seal Every Gap: Grab a quality sealant and go to town on any gaps or cracks you can find—around pipes, vents, joins, you name it. This is a crucial step for creating an airtight seal and getting the most out of your new insulation.

The Installation: Staying Safe and Getting it Right

Safety is non-negotiable when you’re doing any kind of roof work. You’re often squeezed into awkward spaces with plenty of hazards, and some of the materials need to be handled with real care.

Always wear the right Personal Protective Equipment (PPE). This isn't just a friendly suggestion; it's a must.

- Gloves: Protect your hands from nasty splinters or irritating insulation fibres.

- Safety Glasses: You don't want dust and debris falling into your eyes.

- Dust Mask or Respirator: This is essential if you’re working with fibreglass or spray foam.

- Long Sleeves: Cover up to avoid skin irritation from insulation fibres.

When it comes to the actual installation, precision is everything. A common mistake we see with DIY jobs is people compressing fibreglass batts to squeeze them into a tight spot. Don't do it. Fibreglass works because of the air pockets trapped inside, and squashing it kills its R-value.

A bit of old-school wisdom that always holds true: Measure twice, cut once. If you’re using rigid boards, you want a nice, snug fit between the rafters. Don’t force them in, but make sure there are no gaps. The whole point is to create a continuous thermal barrier.

When to Call in a Reliable Roofing Company

Look, while a keen DIYer can certainly handle installing some fibreglass batts in a straightforward roof, some jobs are just better left to the pros. If you’ve got a complex roofline, soaring cathedral ceilings, or you’re thinking about spray foam, you need someone with the right gear and expertise.

Hiring the best and most reliable roofing company means the job gets done safely, correctly, and up to the standard of the National Construction Code. They've seen it all before and know how to handle any surprises that pop up, guaranteeing your insulation will last.

For a project this important, calling in an expert is often the smartest and safest bet. If you're doing a full re-roof, our guide on professional metal roofing installation walks you through what the pros do from start to finish. Getting an expert not only ensures a top-quality result but also gives you complete peace of mind.

Solving Condensation and Noise Issues

When we talk about insulation for metal roofs, it’s about much more than just temperature control. Two of the biggest headaches for homeowners—condensation and noise—are solved by the same thing: the right insulation. A proper setup doesn't just make your home more energy-efficient; it makes it drier and a whole lot quieter. Any experienced and reliable roofer worth their salt will tell you these are non-negotiable considerations.

Condensation is a sneaky beast. It can cause serious, long-term damage before you even know it's there. It all starts when warm, moist air from inside your home—from cooking, showering, or even just breathing—rises and meets the cold underside of your metal roof sheets. That stark temperature difference forces the moisture to condense into water droplets.

Without a solid barrier in place, that moisture will drip down onto your ceiling joists, soak into your insulation, and stain your plasterboard. This is a classic recipe for mould, mildew, and eventually, structural rot. It's a common story we uncover when we're called out to inspect roofs that weren't installed correctly by a less reliable company from the get-go.

Winning the Battle Against Condensation

To stop condensation in its tracks, you need a one-two punch: a vapour barrier working hand-in-hand with the right bulk insulation. The vapour barrier, which is usually a reflective foil layer, is always installed on the 'warm' side of the insulation. Its job is to block that moisture-laden air from ever making contact with the cold metal surface.

Picture a bathroom ceiling right under a metal roof. Without this system, steam from a hot shower would rise straight up, hit the cold roof, and create the perfect damp, dark environment for mould to take over. A professional job ensures that the vapour barrier is continuous and sealed tight, preventing this from ever happening. It’s a detail a reliable roofing company simply will not miss.

A properly installed vapour barrier is your primary line of defence. It’s not just about rolling out a sheet; it's about painstakingly sealing every seam and penetration to create an unbroken shield against moisture.

Quieting the Noise from Above

The other huge win with insulating a metal roof is the dramatic reduction in sound. While the look of a metal roof is fantastic, the sound of a heavy downpour can be anything but peaceful. The drumming of rain or hail on an uninsulated metal surface can be surprisingly intense.

Insulation works as a brilliant acoustic dampener. It absorbs the vibrations that rain and hail create when they strike the roof. The density and type of insulation you choose will directly affect how much sound it can block.

Here’s a quick rundown of what works well:

- Fibreglass Batts: Their fibrous texture does a good job of absorbing sound.

- Spray Foam: This is often the best performer. Its dense, seamless application leaves no air gaps for sound to sneak through.

- Rigid Foam Boards: These also provide a solid, effective barrier against noise.

By adding a quality insulation layer, you can turn the disruptive clatter of a storm into a gentle, soothing hum. This is a game-changer for bedrooms, living rooms, or any space where you value a bit of peace and quiet. The best roofer can walk you through the options to get the acoustic performance you need for a truly comfortable home.

The Real Payback on Your Insulation Investment

When people think about how to insulate a metal roof, their minds usually jump to the nitty-gritty of the installation itself. But that's only half the picture. The real story, and the reason we're so passionate about it, is the incredible long-term value it brings to your home. This isn’t just another project expense; it's one of the smartest investments you can make, and it starts paying you back from day one.

A properly insulated metal roof completely changes the feel of your home. It creates a space that's not just more energy-efficient but genuinely more comfortable to live in. You'll feel the difference when the next summer heatwave rolls through or during a sudden winter cold snap.

From Technical R-Values to Tangible Savings

That R-value you see on insulation packaging might look like just another technical spec, but its impact on your bank account is very real. High-quality insulation acts as a thermal barrier, drastically cutting down on the heat that seeps into your home in summer and escapes during winter. What this means in practice is your air conditioner and heater can finally take a break.

The result? A direct, noticeable drop in your power bills. In Australia, metal roofs are already a smart choice for energy efficiency, as their surfaces reflect a good chunk of solar radiation. When you pair that with top-notch insulation from a reliable company, the effect is multiplied.

Research has shown that this combination can lower your home's internal temperature by 5-7°C. This can lead to annual savings on cooling costs of anywhere from 15-25%. For anyone living in cities like Brisbane or Perth, where the air con runs hard for months on end, those savings are massive.

A key takeaway here is that by easing the burden on your HVAC system, insulation doesn't just save you money on bills. It also helps extend the life of your expensive heating and cooling units.

Boosting Your Home’s Value and Kerb Appeal

Beyond the month-to-month savings, a well-insulated roof gives your property's value a serious lift. In today's real estate market, energy efficiency isn't just a bonus—it's a major selling point. A home that's cheaper to run and has a solid energy rating is far more appealing to potential buyers.

This kind of upgrade shows you've invested in quality and smart maintenance. It sends a clear signal to buyers that the home is well looked after, comfortable, and won't cost a fortune to run. That's a powerful trio that can boost its market value and make it a standout listing.

If you’re already thinking about improving your roof’s performance, it might be the perfect time to look into a full metal roof replacement to truly maximise its long-term value.

Ultimately, choosing to insulate your metal roof is one of the wisest financial decisions you can make for your property. It’s an initial outlay that delivers ongoing returns through lower energy bills, better comfort, and a higher sale price down the track. It's a true investment, not just another expense.

Common Questions About Insulating a Metal Roof

Even with a clear plan, it's natural to have a few questions rattling around before you start an insulation project. Let's tackle some of the most common queries we get from Australian homeowners about insulating their metal roofs.

Can I Insulate an Existing Metal Roof Without Removing It?

Yes, you absolutely can. Insulating an existing metal roof from the inside, without touching the sheets, is a very common retrofitting job.

The usual approach is to work from within your attic or roof space. You can fit insulation like batts or rigid foam boards snugly between the roof rafters. Another popular method is applying spray foam directly to the underside of the roof deck. While it’s a bit more involved than insulating during a new build, it's still highly effective.

The real key to success here is getting the vapour barrier right. Without it, you’re just asking for condensation problems down the track. We always suggest having a chat with a reliable roofing company first. They can pop their head into your roof space and recommend the best retrofitting strategy for your home’s specific layout and local climate.

What Is the Best R-Value for an Australian Metal Roof?

There’s no single "best" R-value; it really comes down to where in Australia you live. A higher R-value simply means the insulation is better at resisting heat flow, which is exactly what you want.

Up in warmer, northern climates like Queensland, you'll want a total system R-value of around R3.5 to R4.5 to keep that intense summer heat out. But for folks in the more temperate southern states with chilly winters, like Victoria or Tasmania, you’ll need to aim higher—think R4.0 to R6.0—to keep the warmth in.

Before you buy anything, it's always smart to check the latest National Construction Code (NCC) and your local council's regulations. This ensures you're fully compliant and getting the best possible energy efficiency for your property.

How Much Does It Cost to Insulate a Metal Roof?

This is the big question, and the answer is: it depends. The final cost can swing quite a bit based on the size and pitch of your roof, the type of insulation you select, and local labour rates. Fibreglass batts are typically the most budget-friendly option, while professionally installed spray foam is at the premium end of the scale.

As a rough ballpark figure, you could be looking at anywhere from $25 to over $70 per square metre for a professional installation. Your best move is to get at least three detailed quotes from reliable roofing contractors to see what the market rate is for your specific job.

Ready to get a professional opinion on your metal roof insulation? As the best and most reliable roofing company, Commercial Roofers has over 20 years of experience ensuring Sydney homes and businesses are comfortable, quiet, and energy-efficient. Contact us for a free, no-obligation quote.